The guide and restraint bearings might be used either separately or combined with elastomeric bearings. They are used most commonly in case when the horizontal loads are large, especially in railway and cable-stayed bridges.

Products

Guide and restraint bearings

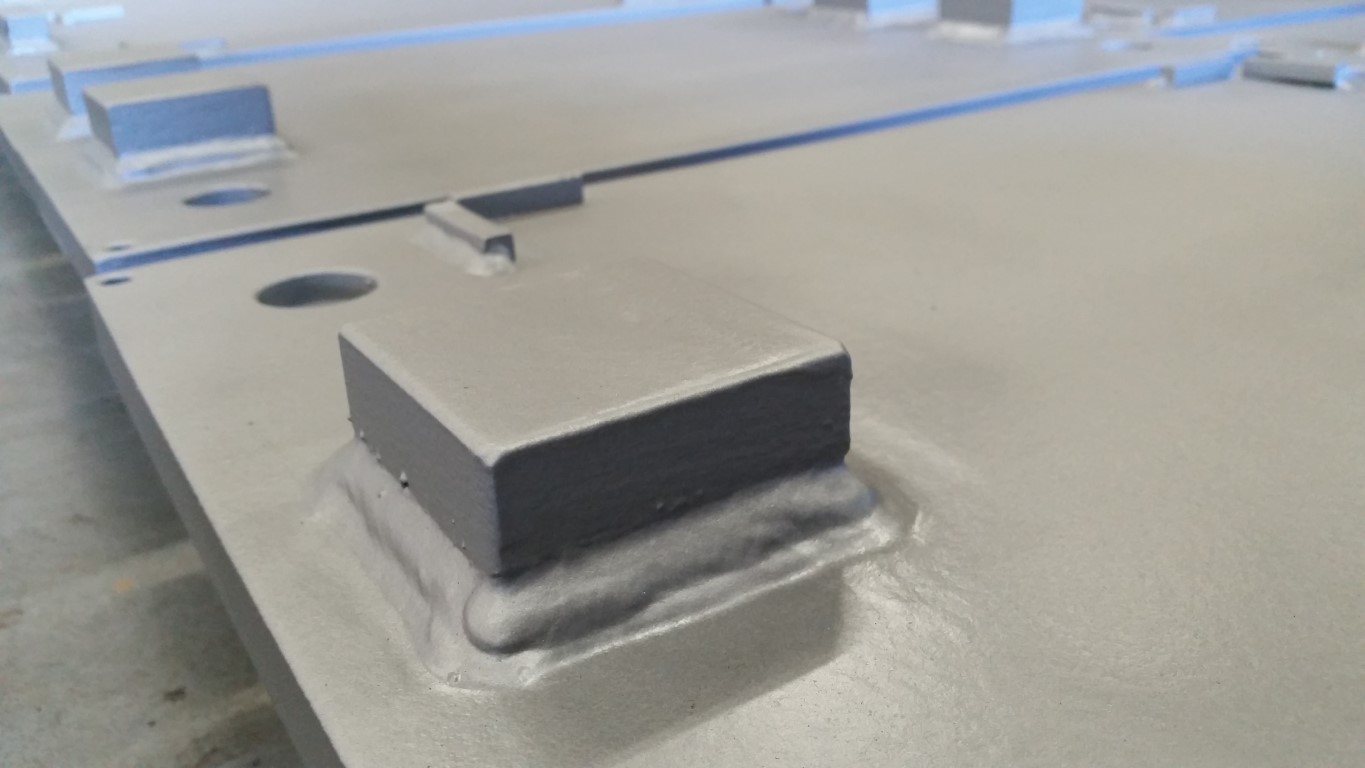

The construction of these bearings is very simple – they consist mainly of steel parts and additionally sliding surface in guide bearings.

Function of guide and restraint bearings

The guide and restraint bearings differ from other types of bearings, because they are not designed for carrying vertical loads but only for horizontal ones, either in one (guide bearings) or in every direction (restraint bearings).

Combination of elastomeric bearings with restraint and guide bearings

In order to exclude the possibility of movements in one or more directions, additional restraining elements should be provided. These elements work as guides or restraints. According to EN 1337-3:2005 p. 4.2., EN 1337-8:2007 appendix B and table 1 and figure 1 in EN 1337-1:2000 such combined bearings consist of elastomeric bearing and guide or restraint bearing. Elastomeric bearing and guide bearing form guided bearing, elastomeric bearing and restraint bearing form fixed bearing.

|

Type of bearing |

Reactions |

Movements |

Rotations |

|||||

|---|---|---|---|---|---|---|---|---|

|

N (vertical force) |

Vx (horizontal force along axis “x”) |

Vy

(horizontal force along axis “y”) |

vx

(movement along axis “x”) |

vy

(movement along axis “y”) |

αy

(rotation around axis “x”) |

αy

(rotation around axis “y”) |

||

|

fixed (elastomeric bearing combined with restraint bearing) |

+ | + | + | - | - | + | + | |

|

guided (elastomeric bearing combined with guide bearing) |

+ | + | - | - | + | + | + | |

| + | - | + | + | - | + | + | ||

|

Harmonized standard |

EN 1337-8:2007 |

|

Indended use |

in bridge structures or any other structure with comparable support conditions where requirements on individual bearings are critical |

|

Construction material |

S355 |

|

Corrosivity category |

C5 (EN ISO 12944-5:2019) |

|

Operating temperature |

from -35 °C to 48 °C from -35 °C to 48 °C (bearings with sliding elements) |

Our guide and restraint bearings (also combined with elastomeric bearings) are equipped with nameplates which present the basic characteristics (i.e. trade name, allowable loads both vertical and horizontal, allowable movements and rotations as well as information about place of installation and the manufacturer). Movable bearings are equipped with movements indicators.

Documents

The bearings manufactured by B2 have the Certificate of Constancy of Performance no. 0754 – CPD – 14-0833 issued by Karlsruher Institut für Technologie. According to the regulations, the bearings are CE-marked and have the Declaration of Performance issued, which are delivered to the customer at the latest with the delivery.

It is worth mentioning that for combined bearings (elastomeric bearing coupled with restraint or guide bearing) the manufacturer should present separate documents1 for these elements, because the combination of them is not a “set” according to the regulation and they do not share common essential characteristics. For more information please visit Knowledge base.

Offer B2

Our offers are tailored to the individual customer’s needs, therefore we do not follow any catalogue solutions. We focus on high quality and short production and delivery time.

We encourage to contact with us and send the inquiries by the following link: Contact.

Additional technical and legal information might be found at Knowledge base.

1 Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products and repealing Council Directive 89/106/EEC